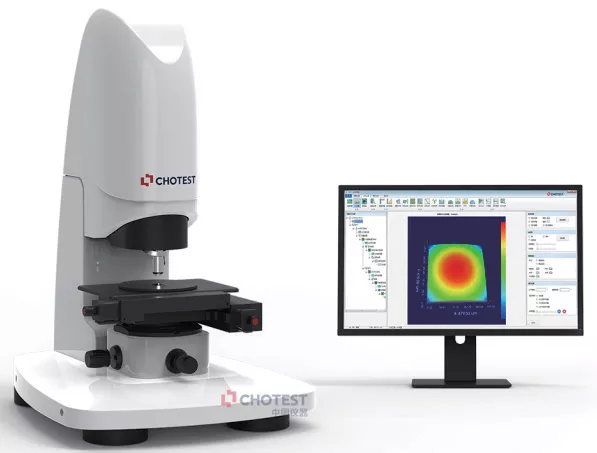

The company has set up a special research and development laboratory, with perfect polishing material preparation, testing, verification, modification and other experimental equipment. It mainly has optical 3D surface profiler, nitrogen adsorption surface area meter, Malvern laser particle size meter 2000, Malvern laser particle size meter 3000, rotary viscometer, constant temperature drying oven, program Muffle furnace, planetary ball mill, plane grinder and other basic equipment, and also has the chemical analysis of iron, praseodymium, cerium, SO, REO, F, etc. Rapid detection ability of Cl and other elements.

Lanzhou University has scientific research and testing channels, With the help of Lanzhou University and Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, X-ray photoelectron spectroscopy, X-ray diffraction, scanning electron microscopy, transmission electron microscopy, atomic force microscope surface analysis, plasma photoelectric direct reading spectrometer, atomic absorption spectrometer, nuclear magnetic resonance and energy spectrometer and other large equipment, The indicators involved can be detected and analyzed.

The company has 13 experienced full-time R & D personnel, including 1 for more than 20 years, 3 for more than 10 years, and 4 for more than 5 years. At the same time, it maintains good cooperative relations with some professors of Lanzhou University, including 2 cooperative professors and 1 researcher. Mainly for rare earth polishing materials, organic complexes, slurry preparation and powder modification cooperation research and development. In cooperation with the reviewer team of international journals such as ASME Journal of Tribology, Jiangnan University, the third generation of wide band gap semiconductor polishing materials was developed.